ABOUT US

Applying Bio-Technology For Sanitation: Promoting Sustainable Solutions for Food Safety, Health, Environment, and Regional Renewal

Since 1970, we have been a leading sanitation consultant, leveraging bioscience technology to address food safety, health, environment, and regional revitalization. With expertise as a registered sanitation inspection agency, we've served over 1,000 clients in public and private sectors, offering inspection and consulting services. Recent expansions include public health services like virus variant monitoring and a Cambodian laboratory for global food safety efforts.

BIO-TEST & ANALYSIS

We offer a wide array of testing services related primarily to food safety,

such as food microbial testing and stool/norovirus testing, as well as analysis required for mandatory nutrition labeling under the amended Food Labeling Act, water quality testing involved in public health, genome analysis, and more.

Food Testing

Testing related to food, such as food microbial testing and nutrient component analysis for nutritional labeling.

Food Sanitation Environment Inspection

Inspection to assess the cleanliness of utensils, facilities, and the environment.

Water Quality Testing

Testing of bathtub water that includes Legionella bacteria testing.

Stool Examination & Norovirus Testing

A test required by mass catering facility sanitation manuals that includes stool testing and norovirus testing.

COVID-19 Genome Analysis Testing

Testing to analyze viral genome sequences and identify mutant strains.

SANITARY CONSULTING

BUSINESS

Leveraging our technology, expertise, and robust information-gathering capabilities, we offer comprehensive assistance to customers in achieving HACCP certification and establishing sanitation management systems. With a proven track record of success, we provide unparalleled support tailored to our clients' needs.

HACCP Certification

We provide support for obtaining HACCP certification from JFS and other industry organizations, for everything from launching a quality control department to support for staff training and creating food safety plans.

Examples of Achievements

Deli foods, seafood, noodles, processed delicacies, etc.

Support for Sanitation Management

We work with experts to solve challenges related to food sanitation, including how to manage sanitation, issues with staff sanitation training, verification of food safety in new product development, and the need for sanitation management due to a change in business format.

Corporate Seminars & Workshops

As the Area Officer of the Japan HACCP Training Center, we conduct Coordinator Development Workshops where participants can obtain qualifications as HACCP Coordinators, as well as seminars to obtain FSPCA PCQI certification required for exporting food to the United States.

We also conduct sanitation study sessions for employees (please inquire regarding content).

*The JHTC HACCP Coordinator Development Workshop textbook and other content has been approved by the International HACCP Alliance. This workshop has also been certified as a designated HACCP training workshop for Class S Delicatessen Managers in the Japan Ready-Made Meal Association and meets the criteria for more than 16 hours of private certification in HACCP.

GLOBAL BUSINESS

For Food Safety and Security Worldwide

Since 2011, we have conducted surveys on food sanitation environments in Cambodia and other ASEAN countries.

Particularly in Cambodia, there is a significant disparity in food sanitation compared to developed countries, making building inspection laboratories that meet global standards and training knowledgeable technicians an urgent national priority. That is why we established SPEC Cambodia in 2014. This has a laboratory capable of conducting tests according to ISO standards as well, where we have been conducting monitoring surveys on food safety in collaboration with the Cambodian government and with the support of JICA since 2023. Going forward, we will recommend necessary sanitation management based on monitoring test data to contribute to food sanitation in Cambodia.

QUALITY CONTROL

The most important aspect of testing is test result accuracy. However, values inevitably vary across processes such as sample collection, transportation, and measurement. To provide customers with reliable test results, we do something called "accuracy control" to understand the magnitude of this variation and to improve accuracy. We conduct both external accuracy control and internal accuracy control to assess testing techniques. Having this accuracy control system allows us to deliver reliable test results.

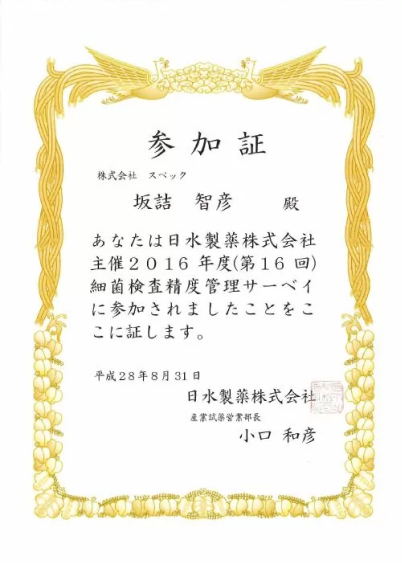

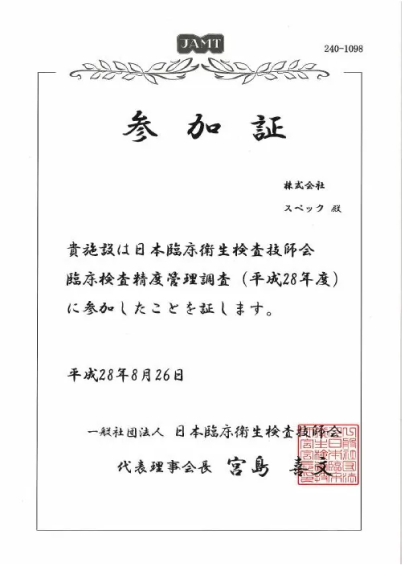

External Accuracy Control

This means participating in testing at external organizations and assessing results in order to assess testing techniques. This lets an organization check the accuracy of its own test results by comparing them with the average or target values of participating facilities. In clinical testing, we participate in testing conducted by the Japanese Association of Medical Technologists. In food testing, we participate in testing conducted by Shimadzu Diagnostics Corporation (formerly Nissui Pharmaceutical Co., Ltd.).

Internal Accuracy Control

This means conducting tests within the company using samples with known concentrations to assess testing techniques. Examining the reproducibility of measured values and the range of errors when the same test is repeated allows us to assess the accuracy of testing.

CONTACT

See here for business-related inquiries or consultations

CONTACT

See here for business-related inquiries

or consultations

COMPANY PROFILE

Branch Offices

(Bioscience testing and analysis services)

- ・Tokyo Office

- ・Takamatsu Office

- ・Kochi Office

- ・Matsuyama Office

- ・Okayama Office

- ・Nagoya Sales Office

- ・Kitakyushu Office

- ・Kumamoto Office

- ・Cambodia